Lightweight thermal insulation refractory bricks are a type of brick material with excellent thermal insulation and refractory properties,

which are widely used in high-temperature industrial furnaces, chimneys, heating furnaces and other fields.

Its manufacturing process, raw material composition, advantages and disadvantages and scope of application are as follows:

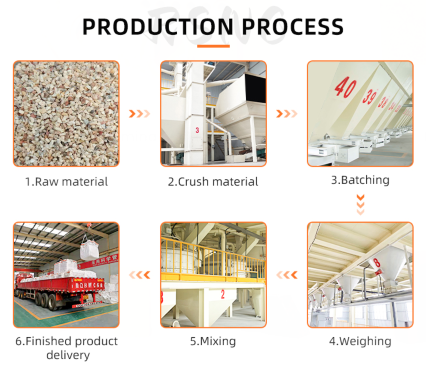

Lightweight thermal insulation refractory bricks manufacturing process.

1)𝐑𝐚𝐰 𝐦𝐚𝐭𝐞𝐫𝐢𝐚𝐥 𝐩𝐫𝐞𝐩𝐚𝐫𝐚𝐭𝐢𝐨𝐧: Select suitable raw materials, including refractory clay, expansion agent, additives, etc.

2)Mixing: Mix the refractory raw materials and expansion agent evenly. The expansion agent will expand at high temperature to form pores inside the brick body, thereby enhancing the thermal insulation performance of the brick.

3)Molding: Put the mixture into a mold and make a brick blank through a press or other molding equipment.

4)Drying: Dry the formed brick blank to remove excess moisture and prevent cracks during firing.

5)Firing: Firing in a high-temperature furnace. During the firing process, the expansion agent causes pores to form inside the brick body, enhancing the thermal insulation performance.

Refractory bricks Raw material composition.

1)Refractory raw materials: such as high-alumina ore, silica, magnesia, etc., these raw materials give the brick excellent refractory properties.

2)Expansion agent: such as aluminum powder, expanded perlite, etc., used to form pores to enhance the lightweight and thermal insulation properties of the brick.

3)Additives: including binders and stabilizers, which help improve the strength and structural stability of the brick.

Lightweight thermal insulation bricks advantages.

1. Good thermal insulation performance: Since the brick contains a large number of pores inside, it can effectively reduce heat conduction and improve the thermal insulation effect.

2. Strong refractory performance: It can withstand high temperatures, is not easy to melt or deform, and is suitable for high temperature environments.

3. Light weight: Compared with traditional refractory bricks, lightweight thermal insulation refractory bricks are lighter, which reduces the difficulty of transportation and construction.

4. Energy saving: It effectively reduces energy consumption, especially in industrial furnaces and heating equipment, which can reduce energy consumption.

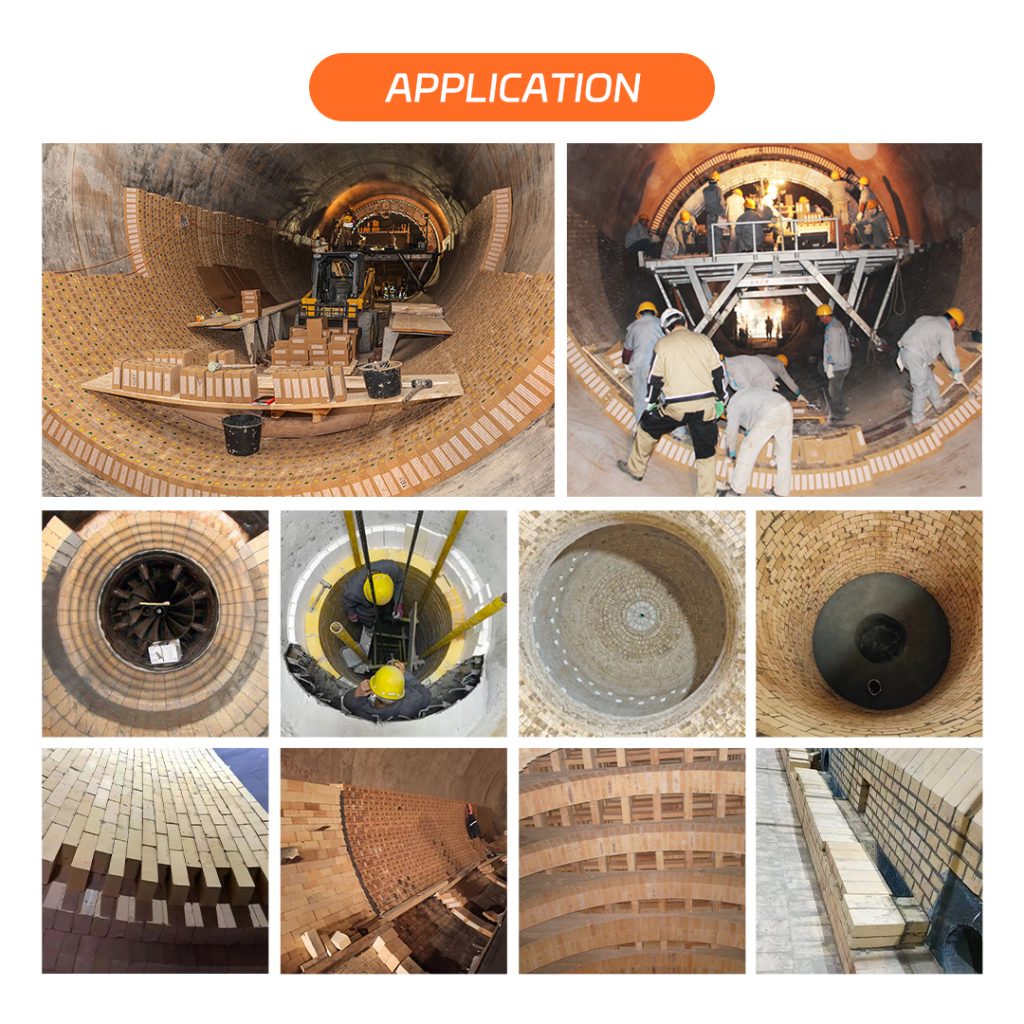

Scope of application

Lightweight thermal insulation refractory bricks play an important role in many high-temperature application scenarios due to their excellent thermal insulation and refractory properties, but it is also necessary to pay attention to their limitations in strength and water resistance.

1. High-temperature industrial furnaces: such as furnaces in the steel, metallurgy and other industries, used for insulation and refractory of furnace walls and furnace bottoms.

2. Chimneys: used for the inner wall of chimneys, to withstand the erosion and heat of high-temperature gases.

3. Heating furnaces: such as glass melting furnaces, ceramic kilns, etc., require heating equipment to maintain stable temperature.

4. Thermal power plants: used for the insulation layer of boilers and steam generators to reduce heat loss and improve efficiency.